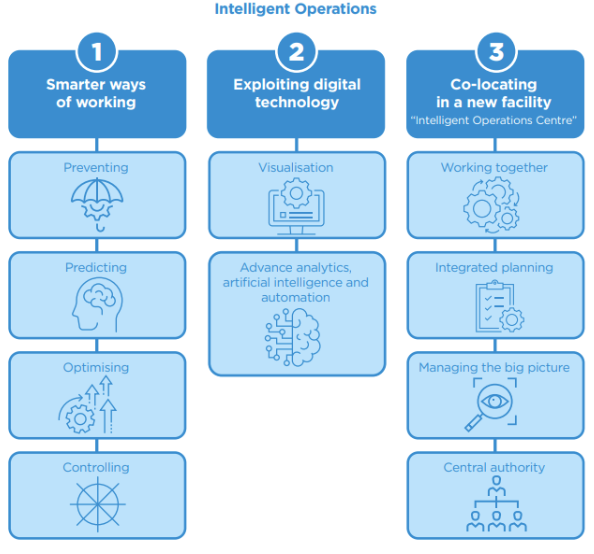

Intelligent Operations comprises smarter ways of working to:

- Ensure a more preventative approach to maintenance of assets;

- Predict when issues are about to occur and intervene sooner;

- Set up and tune our end-to-end water and wastewater system to run at its optimum state; and

- Establish more central control of assets.

This is enabled through the deployment of data, digital and visualisation technology with a new Intelligent Operations Centre. The centre facilitates much greater collaboration between operational staff, leadership and supporting teams working together to deliver service improvements and efficiencies.

Pumping and blowing accounts for around two thirds of our electricity needs. We are deploying intelligent controls to our treatment processes, including major pumps and blowers, to minimise energy usage and to operate at times of lower power prices.

We have implemented real time control (RTC) technology and process control measures at a number of our wastewater treatment works over PC15 and PC21 periods. The purpose of RTC is to efficiently manage the amount of air pumped by blowers in secondary treatment process to minimise the energy usage whilst ensuring compliance with discharge consents are achieved. The technology not only helps us deliver energy efficiencies, it also provides the ability for the treatment works to quickly respond to any change in effluent quality, to ensure compliance is not compromised.

The data from meters and sensors is made available to our Intelligent Operations Centre, allowing more central control of our assets and supporting reductions in our energy demand. We’ve installed meters and sensors required to bring dashboards to life that will provide the insight into pump efficiency, reduce use in peak charging periods and increase night-time running.